There are many types of hydraulic valves: ball valves, manual valves, cartridge valves, solenoid/directional control valves, flow-control valves, check valves, needle valves and relief valves.

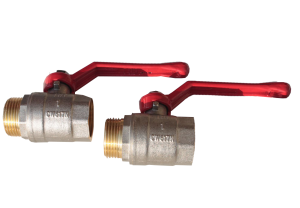

Ball Valves

Ball valves are some of the most simplistic and accurate valves. They have a ball in the middle of the valve, that turns when the handle is turned. Once turned, fluid is able to pass through the perforation in the ball. When turned back to its starting position, the side of the ball cuts off the fluid flow once again. Featuring 2- or 3-way positions, hydraulic ball valves are perfect for almost any industrial application. Ideal for high pressure applications, ball valves are available in steel and stainless steel, and manual or motor actuated. PDI’s ball valves ensure that fluid is delivered to the correct location every time.

Ball valves are some of the most simplistic and accurate valves. They have a ball in the middle of the valve, that turns when the handle is turned. Once turned, fluid is able to pass through the perforation in the ball. When turned back to its starting position, the side of the ball cuts off the fluid flow once again. Featuring 2- or 3-way positions, hydraulic ball valves are perfect for almost any industrial application. Ideal for high pressure applications, ball valves are available in steel and stainless steel, and manual or motor actuated. PDI’s ball valves ensure that fluid is delivered to the correct location every time.

Manual Valves

Manual valves simply refer to any valves that requires manual operation, like a lever. These valves start and stop fluid flow through a valve. PDI’s manual valves come in 1 ,2 and 3 spool options, depending on the application. Common applications for manual valves are in log-splitting operations, agricultural equipment such as backhoes, to garbage compactors.

Manual valves simply refer to any valves that requires manual operation, like a lever. These valves start and stop fluid flow through a valve. PDI’s manual valves come in 1 ,2 and 3 spool options, depending on the application. Common applications for manual valves are in log-splitting operations, agricultural equipment such as backhoes, to garbage compactors.

Cartridge Valves

Cartridge valves are a specific type of technology that are excellent in hydraulic fluid control applications as they are compact, economical and versatile.

Cartridge valves are a specific type of technology that are excellent in hydraulic fluid control applications as they are compact, economical and versatile.

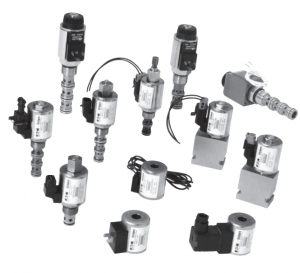

Directional Control Valves

Directional control valves are one of the most basic components in a fluid power system. Their function is to allow fluid flow, stop the flow and to change the direction. When selecting a directional control valve, you must decide how many fluid ports are needed, and how many directions you want the valve to achieve.

Directional control valves are one of the most basic components in a fluid power system. Their function is to allow fluid flow, stop the flow and to change the direction. When selecting a directional control valve, you must decide how many fluid ports are needed, and how many directions you want the valve to achieve.

Directional control valves can also be known as solenoid valves. Solenoid operated directional control valves are actuated by electricity rather than manually operated. These 2-, 3- and 4- way control valves are available in 2 or 3 positions and in various sizes depending on the psi and gpm required. They are available in different sizes and threads, such as NPT and SAE.

Flow-Control Valves

Flow control valves do exactly what it sounds like. These valves allow you to regulate and adjust the hydraulic fluid flow. Flow-control valves are manually adjusted valves that control flow in one direction and full flow in the opposite direction. Can be inline valves or as part of a stack on a hydraulic manifold. They are available in different sizes and threads, such as NPT and SAE.

Flow control valves do exactly what it sounds like. These valves allow you to regulate and adjust the hydraulic fluid flow. Flow-control valves are manually adjusted valves that control flow in one direction and full flow in the opposite direction. Can be inline valves or as part of a stack on a hydraulic manifold. They are available in different sizes and threads, such as NPT and SAE.

Check Valves

Check valves are valves that allow flow to occur in one direction and prevent backflow. Once flow stops or reverses, the valve closes. Temperature ranges of -40-400°F. Check valves can be inline or manifold-mounted and ordered with various check pressures.

Check valves are valves that allow flow to occur in one direction and prevent backflow. Once flow stops or reverses, the valve closes. Temperature ranges of -40-400°F. Check valves can be inline or manifold-mounted and ordered with various check pressures.

Needle Valves

Needle valves are flow-control valves can can adjust the flow rate in both directions. The variable orifice features a clockwise rotation and handle all flow rates. Temperature ranges of -40-400°F and a pressure of up to 5,000 psi with up to 20 gallons per minute flow. Our valves come standard with lock nuts.

Needle valves are flow-control valves can can adjust the flow rate in both directions. The variable orifice features a clockwise rotation and handle all flow rates. Temperature ranges of -40-400°F and a pressure of up to 5,000 psi with up to 20 gallons per minute flow. Our valves come standard with lock nuts.

Relief Valves

Also known as pressure relief valves (PRV), relief valves are safety valves that limit or control pressure in a system. Too much flow can cause negative pressure rise. Relief valves are suitable for continuous duty with reliable response.

Also known as pressure relief valves (PRV), relief valves are safety valves that limit or control pressure in a system. Too much flow can cause negative pressure rise. Relief valves are suitable for continuous duty with reliable response.