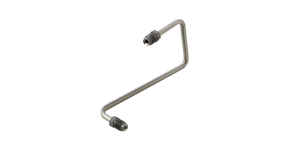

So your project requires hydraulic tube bending. You’re in luck. Here at Power Drives, we’re experts in hydraulic hose and tube, as well as fluid treatment and conveyance in general. Hydraulics has been our focus since 1946, and we’ve only gotten better and more diversified over the years.

As you start your project, you may find that looking for steel or stainless steel tube bending can leave you with more questions than answers. You know your application requirements and likely the material you need (steel or stainless steel), but beyond that, it really comes down to determining the right supplier. The right supplier will act as a partner to you, helping to determine the diameter, wall thickness, bend and configuration of your hydraulic tube.

There are a number of ways to bend hydraulic tube, including CNC (Computer Numerical Control)

bending and manual bending. CNC bending is more precise and efficient, which is why here at Power Drives, this is our main method of bending. We use CNC bending equipment to bend a wide range of materials to meet each specific customer application and ensure specification consistency throughout production. We create custom bent tube to a wide variety of exacting standards and wall thicknesses. Our tube diameter bending capability is from 3/16″ to 3″.

For any high production job, CNC bending is a no-brainer, as it can turn out perfectly specified bends at near-lightning speed.

Contact us today to discuss your project and how the fluid power experts at PDI can make it a reality for you.